What is Schedule 40 PVC Conduit?

Categories:News Author: author

Schedule 40 PVC conduit is not only a master of physical protection, but also a wise expert in environmental protection.

Faced with the challenges of harsh environments such as humidity, corrosion, and even fire hazards, Schedule 40 PVC conduits have built an indestructible barrier for cables with their excellent weather resistance and flame retardant properties.

The sch 40 conduit materials are covers metal, plastic, fiber, fired clay, etc. Appearance forms include rigid pipes and corrugated pipes, and corrugated pipes are generally used for specific purposes.

What is Schedule 40 PVC Conduit?

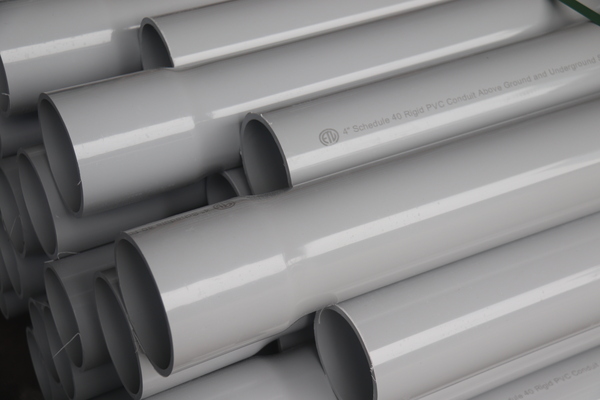

Schedule 40 PVC conduit is a rigid PVC pipe designed to protect and route electrical wiring in a building or construction.

‘Schedule 40’ or ‘sch 40’ is the North American nominal pipe size (NPS), which has been replaced by ASTM and other standards over time.

Metal

- Rigid Metal Conduit (RMC)

Schedule 40 Rigid Metal Conduit is a type of galvanized steel conduit with standardized wall thickness, used for protecting wiring in various applications.

- Galvanized Rigid Conduit (GRC)

Schedule 40 Galvanized Rigid Conduit is a type of galvanized steel electrical conduit with standardized wall thickness, offering enhanced protection against corrosion.

- Aluminum Conduit

Schedule 40 Aluminum Conduit is a type of aluminum electrical conduit with standardized wall thickness, offering a cost-effective and durable option for various applications.

- Non-metallic

Schedule 40 80 Non Metallic Pvc Conduit Pipe Wholesales

- PVC Conduit

Sch 40 PVC conduit is the most common wire conduit now. Compared with metal conduits, it has the advantages of being lightweight and lower cost, and its hardness is not weaker than metal conduits. That’s why schedule 40 & 80 conduits belong to this type.

PVC conduit has been developed for many years. So the manufacturing and process are stable, and the fittings family is almost complete. Smart designers use various innovative designs to make quick installation and removal accessories, which can greatly improve installation efficiency and save huge labor costs.

Specifically, it can be listed in the following categories,

- Reinforced Thermosetting Resin Conduit (RTRC)

Also known as a fiberglass conduit, its biggest advantage is lightweight. And the fiberglass conduit is also installed in placements that require high corrosion resistance of wire conduits, such as seaside buildings.

- Rigid Nonmetallic Conduit (RNC)

It is still a rigid conduit but has no threads and is very smooth inside, which is suitable for protecting wires. The well-known Schedule 40 & 80 PVC Conduit belongs to this type;

8 Benefits of Schedule 40 PVC Conduit?

The benefits of Sch 40 PVC conduit are,

- 1. Cost-Effectiveness

Schedule 40 Conduit is generally less expensive than metal conduits like steel or aluminum, making it a budget-friendly choice for many projects.

- 2. Lightweight & Easy to Work With

PVC’s lightweight nature simplifies installation and handling, reducing labor costs and making it ideal for DIY projects. It’s also easy to cut and thread with standard tools.

- 3. Excellent Corrosion Resistance:

PVC conduit is highly resistant to corrosion from moisture, chemicals, and even soil, ensuring long-lasting performance in demanding environments.

- 4. Durability & Impact Strength

Despite its lightweight nature, Schedule 40 PVC offers good impact resistance, able to withstand bumps and accidental damage.

- 5. Electrical Insulation

PVC itself acts as an insulator, providing a layer of protection against electrical shocks.

- 6. Flame Retardant Properties

Most Schedule 40 conduits are flame retardant, reducing the risk of fire spread in case of an electrical hazard.

- 7. Simple Installation

Sch 40 conduit can be easily joined using solvent cement, creating secure and watertight connections.

- 8. Wide Range of Applications

Schedule 40 PVC is suitable for both indoor and outdoor installations in residential, commercial, and industrial settings.

6 Benefits of Sch 40 Metal Conduit

Here are the key benefits of using Schedule 40 metal conduit (often steel or aluminum).

- 1. Superior Strength & Durability

Sch 40 metal conduits offer significantly higher strength and durability compared to PVC, making them ideal for demanding applications where impact resistance is crucial.

- 2. Long-Lasting Performance

Metal resists corrosion exceptionally well, especially when galvanized (coated with zinc), ensuring longevity even in harsh environments.

- 3. Fire Resistance

Schedule 40 metal conduit offers excellent fire resistance, limiting the spread of flames and providing additional safety in case of electrical hazards.

- 4. Electromagnetic Interference (EMI) Shielding

Metal acts as a Faraday cage, effectively shielding sensitive electronic equipment from electromagnetic interference.

- 5. Grounding Capability

Schedule 40 Metal conduits provide an inherent grounding path, enhancing electrical safety by facilitating the safe dissipation of fault currents.

- 6. Flexibility in Installation

While heavier than PVC, sch 40 metal conduit comes in various sizes and configurations (e.g., threaded or grooved), allowing for adaptability in different installation scenarios.