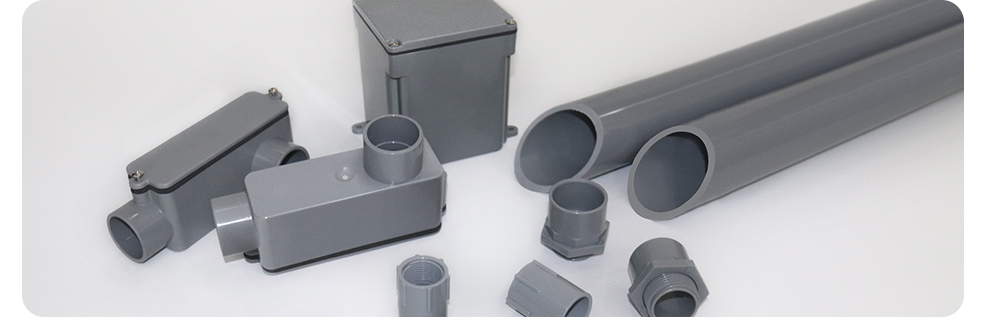

UL651 schedule 40 electrical conduit

| Raw material | PVC | |||||||

| Standards | ul651 | |||||||

| Length | 10ft. or 20ft. | |||||||

| Color | Grey or customized to suit your project needs | |||||||

| Application |

Underground and above construction |

|||||||

| Feature | Character-flame resistant, UV resistant, corrosion resistant, etc | |||||||

| Custom made | Flexiable OEM/ODM-size, colors, packaging can be customized | |||||||

| Tensile strength | 5,000 psi (3.45 KN/cm²) | |||||||

| Extrusion | Fusion | |||||||

| Water absorption | ﹤0.50% of whole weight after soak | |||||||

| Resistance to crushing | ID≥70% after test | |||||||

| Resistance to impact | Less than 3 of 1/32 inch cracks & tears | |||||||

| Deflection unde load | ﹤0.25mm deformation | |||||||

| Fire rating | UL 94V-0 | |||||||

| Resistance to specific reagents | Less ±2.50% weight after 60 / 120 days soak | |||||||

| Permanency of printing | Yes | |||||||

| Rust & sunlight Resistant | Yes | |||||||

| Shipping | By sea | |||||||

| Samples | Available | |||||||

Regular sizes as shown in the table below

| Size | Average O.D.(in) | Average O.D.(nm) | SCH40 Minimum wall | SCH80 Minimum wall | Length or customize | ||||

| 1/2" | 0.840 | 21.3 | 0.109 | 0.147 | 10/20 | ||||

| 3/4" | 1.050 | 26.7 | 0.113 | 0.154 | 10/20 | ||||

| 1" | 1.315 | 33.4 | 0.133 | 0.179 | 10/20 | ||||

| 1 1/4" | 1.660 | 42.2 | 0.14 | 0.191 | 10/20 | ||||

| 1 1/2" | 1.900 | 48.3 | 0.145 | 0.200 | 10/20 | ||||

| 2" | 2.375 | 60.3 | 0.154 | 0.218 | 10/20 | ||||

| 2 1/2" | 2.875 | 73.0 | 0.203 | 0.276 | 10/20 | ||||

| 3" | 3.500 | 88.9 | 0.216 | 0.300 | 10/20 | ||||

| 3 1/2” | 4.000 | 101.5 | 0.226 | 0.318 | 10/20 | ||||

| 4" | 4.500 | 114.3 | 0.237 | 0.377 | 10/20 | ||||

| 5" | 5.563 | 141.3 | 0.258 | 0.375 | 10/20 | ||||

| 6" | 6.625 | 168.3 | 0.280 | 0.432 | 10/20 | ||||

Information to be marked on conduits

(A)The phrase “Rigid PVC conduit”.

(B)The name or trademark of the manufacturer or any other distinctive marking by means of which the organization responsible for the product can be readily identified.

(C) The date or other dating period of manufacture not exceeding any three consecutive months.

(D) The trade size of the conduit product.

(E) All markings shall be repeated at uniform intervals and shall appear at least every 10 feet (3.05m), but not less than once, on each dtraight length of PVC conduit.

For an elbow the date of manufacture is to be the date that

(1) The elbow was formed, where the conduit is extruded at a different location.

(2) The conduit is extruded when both extrusion and bending occur at the same location.

(1) What is schedule 40 electrical conduit?

Schedule 40 electrical conduits are pipes based on the nominal pipe size (NPS) standard size, generally available in plastic or metal, which is designed for underground or above installation that protects the cable wires.

(2)What is schedule 40 conduit used for?

The purpose of schedule 40 electrical conduit is to provide a protective, durable pathway for cable wires in building construction, ensuring both electrical systems and telecommunications networks remain secure.

Used for electrical wiring in walls, floors, and ceilings, These PVC conduits adhere to NEC 352 standards and can be directly buried into the earth, encased in concrete, or utilized in areas exposed to sunlight. They are designed to safeguard network cables, fiber optic cables, and other data wiring from damage and interference.

Schedule 40 PVC electrical conduit pipe is used for electrical cable in walls, floors and ceilings in accordance with national electrical code (NEC) 352. Schedule 40 PVC electrical conduit is approved for various applications.

These include

(1) Concealed installations (2) Supporting conduit bodies (3) Areas with cinders (4) Wet iocations

(5) Dry and damp iocations (6) Exposed installations (7) Underground installations

(8) Environments with corrosive influences

(3)Here’s What Sets us Apart

Certification: Our PVC electrical conduit conforms to the requirements of ul and ETL standards and has excellent safety.

New materials: Made with 100% new materials, pursuing ultimate quality and performance.

Excellent fire resistance: UL 94V-0 Fire rating ensures rapid fire extinguishing, providing protection for your home or building.

Unparalleled durability: Heat resistance, sun resistance, and corrosion resistance ensure a long-lasting and reliable solution.

Strength:ULP is a leading manufacturer of high-quality electrical conduits, trusted by industry professionals for 10 Years+.ULP bringing you complete, beneficial, convenient, and high-quality electrical conduit and accessory products.

(4)We believe in

Safety first: Building reliable and safe electrical systems.

Quality craftsmanship: Precise engineering and attention to detail.

Customer satisfaction: Providing exceptional support and solutions.

Get exclusive solutions for your project immediately!

Contact ULP >> to learn about the differences in high-quality electrical conduits.

Our schedule 40 electrical conduit and accessories are designed to handle even the most demanding electrical projects.

(1)Extraordinary strength: Can withstand up to 5,000 psi tensile force.

(2)Flexible deflection: Minimizes risks with a mere 0.25mm deflection under load.

(3)Industry-leading compliance: Meets and exceeds ul651 and ETL standards for ultimate peace of mind.

(1)Superior quality: ULP Schedule 40 PVC pipes have a series of impressive advantages: heat resistance, corrosion resistance, fire resistance, and sun resistance. (2)Increased efficiency: Save money by avoiding costly delays.

(3)Effortless installation: No more time-consuming prep work before installation.

(1)Rapid extinguishing: The fire is quickly extinguished when the fire source is cut off.

(2).Harmless safety: Using ULP SCH40 conduits,This advanced technology minimizes potential damage and keeps you and your property protected.

our electrical conduit pipes excel in outdoor installations.

(1)Heat resistance: Sunlight & UV resistance support.

(2)UV resistance: Stands strong against the damaging effects of sunlight.

(1)Lightweight construction: Easy to handle and install.

(2)Cost-effective solution:More durable and affordable than metal pipes, with cheaper shipping costs.

(3)Corrosion-proof: Enjoy lasting performance with guaranteed protection against rust.

With over 10 years of experience in the foreign trade of plastic piping.

ULP produce and distribute nationwide, providing one-to-one services to numerous companies in various countries such as the united states and australia.

our professional team can tailor perfect solutions according to your unique needs. experience the safety and reliability of ULP electrical conduits!

Get the full price list now by contact our sales team. >>

(1)OEM&ODM

OEM/ODM options are available for sizes, colors, and packaging.

(2)Quality

Provide overall solutions for various high-quality plastic pipes and accessories products.

(3)Price

Can be negotiable with flexible solution.

(4)Main Business

Supply PVC Electrical Conduit & Fittings:

(1) Rigid and corrugated conduit pipe for electrical, building, and communication projects. SCH40, SCH80, DB60, DB100, DB120 PVC electrical conduit (UL & ASTM certified)

(2) Heavy duty & medium duty conduit (AS/NZS Certified)

(3) DB2 & ENT conduit (CSA & CUL certified)

(4) Solar conduit (IEC & AS/NZS certified)

(5) LSZH rigid & corrugated conduit (IEC & ISO certified) and that’s just the tip of the lceberg!

(6) We also offer a wide variety of electrical box, bend, coupling, tee, elbow,ib bodies, reducer, connectors, adapter, bushing, cap and more.